24 liter Europa B autoclave with printer

Professional autoclave model Europa Class B, 24 liter capacity with integrated printer.

Are you in UK or outside Euro Zone?

Are you in UK or outside Euro Zone?

You will not pay Italian 22% VAT

Are you a Doctor or a Professional?

Are you a Doctor or a Professional?

Sign in here to obtain reserved price list

Fast shipping throughout Europe

Fast shipping throughout Europe

We use only premium couriers

Professional autoclave model Europa Class B, 24 liter capacity with integrated printer.

An autoclave for type B loads allows you to sterilize hollow bodies such as handpieces and turbines and porous materials (gowns, gauze...).

PID System (Proportional Integral Derivative)

It is the maximum expression of closed-loop controls. It ensures constant control and monitoring of the entire functional system of the autoclave, intervening automatically in the event of anomalies on incorrect technical and electronic parameters.

Tanks inside the machine

In the event of accidental insertion of inadequate liquids, the autoclave tanks can all be inspected and cleaned, as required by technical regulations. All autoclaves have a pure water tank and a used water tank inside them. Each tank is equipped with probes to signal the maximum and minimum levels.

Preset temperatures

The temperatures set on the cycles of our autoclaves are 134°C and 121°C. The 134°C cycles are normally used for the sterilization of solid and ferrous materials. 121°C cycles are used for thermoplastics and sensitive materials.

Ease of use

The sterilization cycle is chosen by pressing one button and activated by pressing another. The first allows you to scroll and view the data relating to each cycle on the large display to then select the most suitable one, the second automatically starts the entire sterilization cycle. For any error or alarm, messages and LED signals will call your attention.

Fully automatic cycles

All phases are managed by the advanced board complete with powerful microprocessor. Each phase (vacuum, preheating, exposure time, drying) is monitored, supported and managed automatically.

Cycles without operator with automatic shutdown

During sterilization cycles, an automatic function starts an anti-condensation phase and automatic shut-off in the absence of an operator at the end of the cycle.

Test cycles

Our autoclaves are complete with test cycles for their periodic control via physical and functional systems. Helix test to evaluate the vacuum capacity in hollow bodies. Bowie & Dick to evaluate the vacuum capacity in porous bodies. Vacuum test to evaluate the vacuum holding capacity.

Constant monitoring of cycles

A device ensures constant control and monitoring of the sterilization cycles. Any type of anomaly is detected and immediately blocked if it jeopardizes the sterilization cycles. The operator is informed of the anomaly via a message.

All cycles ensure the sterilization of type B loads

All sterilization cycles have a fractional vacuum system, controls and parameters that ensure the sterilization of type B loads. Even an incorrect selection of the desired cycle always ensures safe sterilization on every type of material treated.

Integrated adosmosis system

Water treatment that eliminates even the smallest polluting particles, ensuring bacteriological purity. It works through an osmotic membrane that filters water at a molecular level.

Autoclave equipped with built-in printer.

Supplied with a closed tray holder, 4 aluminum trays, 1 dual-use key (to extract the trays and to adjust the door), water inlet and outlet hoses, cleaning sponge and integrated osmosis system.

Technical features

• External dimensions: 510 x 390 x 730 mm (W x H x D)

• Chamber dimensions: 245 x 500 mm (Ø x depth)

• Operating voltage 230 V - 50/60 Hz

• Maximum absorbed power: 2,200 W

• Weight: 58kg

• Integrated printer: YES

• Manual closing: YES

• Pure deionizer preparation: YES

• PID system: YES

• Cycles: 121°C Wrapped

• Min-max operating pressure: 1.04 - 1.30

Minimum total cycle time *: 56 minutes (25 + 18 + 13)

• Cycles: 121°C Unwrapped

• Min-max operating pressure: 1.04 - 1.30

• Minimum duration of the total cycle *: 55 minutes (25 + 18 + 12)

• Cycles: 134°C Flash

• Min-max operating pressure: 2.02 - 2.38

• Minimum duration of the total cycle *: 33 minutes (25 + 4 + 4)

• Cycles: 134°C Wrapped

• Min-max operating pressure: 2.02 - 2.38

• Minimum duration of the total cycle *: 43 minutes (25 + 5 + 13)

• Cycles: 134°C Unwrapped

• Min-max operating pressure: 2.02 - 2.38

• Minimum duration of the total cycle *: 42 minutes (25 + 5 + 12)

• Cycles: 134°C Prion

• Min-max operating pressure: 2.02 - 2.38

• Minimum duration of the total cycle *: 58 minutes (25 + 20 + 13)

Data sheet

- CE Certification:

- Yes

Specific References

You might also like

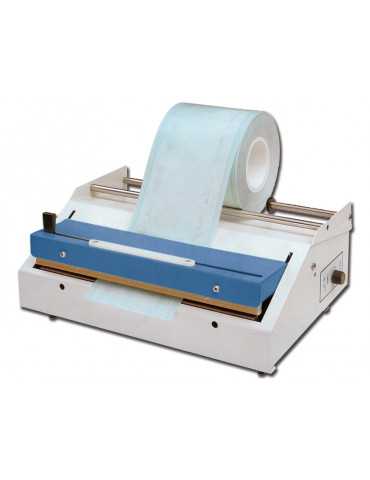

D-400 automatic heat sealer without printer

zł9,203.18 VAT Excl.

Automatic roller heat sealer, model D-400 without printer with automatic photocell dragging system.